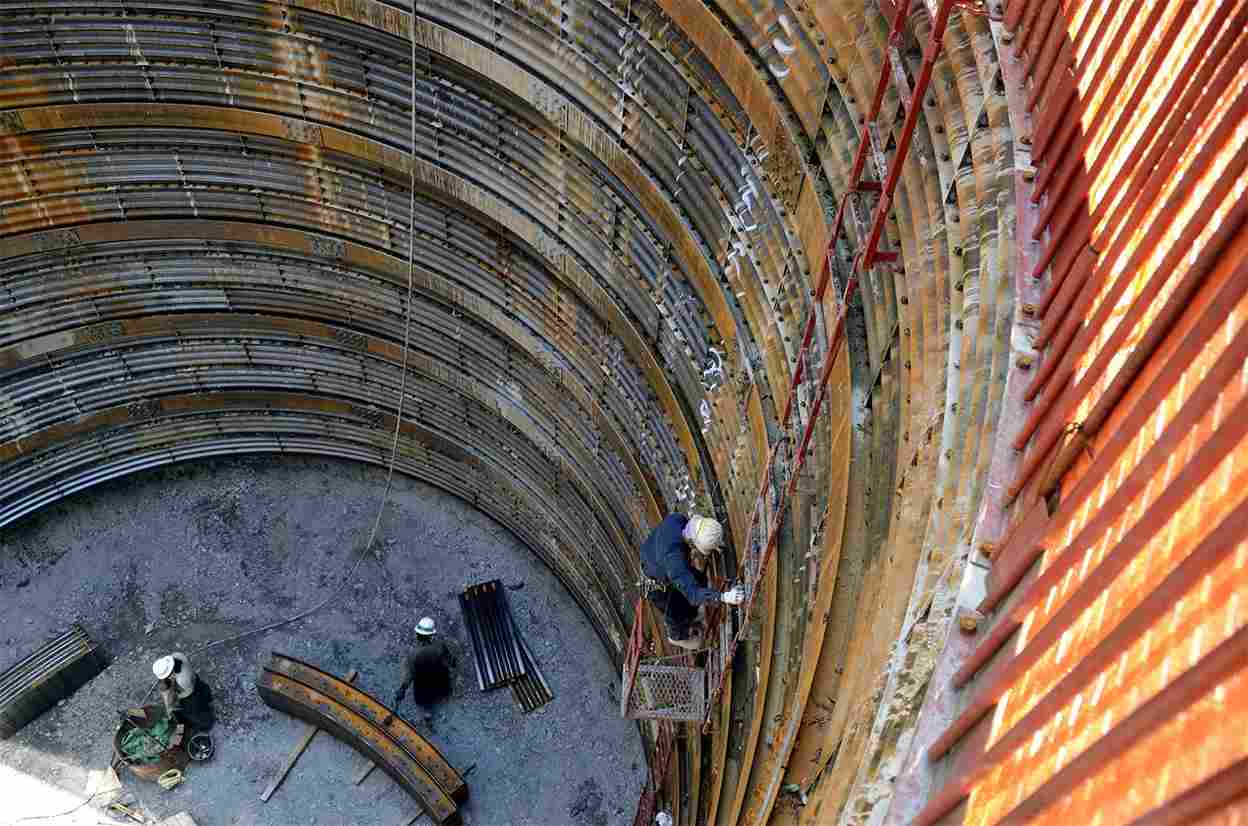

Caisson foundations are box-type, watertight structures built to retain water or other loose materials to construct piers for a bridge. They are generally constructed above ground and then driven down to the required depth.

Caisson foundations are suitable for underwater constructions for bridges and docks or any other structure that requires underwater foundations. They are large in diameter and can be made up of RCC (Reinforced cement concrete), timber or steel.

It is a type of deep foundation used when a stratum of sufficient bearing capacity is found below the loose or soft surface layers.

What is the Caisson Foundation’s Function?

- Caisson provides a firm platform for the piers and transfers all the loads to the soil.

- Being underground, a pier sustains heavy horizontal forces exerted by water, caisson acts like an anchor and keeps the structure stable.

- Caisson prevents any damage to the structure due to uneven soil settlement.

Different Types of Caisson Foundation

There are three types of Caisson foundations:

Box Caissons

Box caissons can be made of concrete, steel or even timber. They are closed at the bottom and open at the top. They are constructed off-site and then transported to the site to be sunk to the required depth.

They are suitable for a project where the load is not too heavy and soil of sufficient bearing capacity is not too deep. They are relatively affordable to construct.

Open Caissons:

Open caissons are open at both ends. They can be constructed with steel, timber, masonry or concrete. They are also known as wells. They can be sunk very deep and are affordable to construct.

Pneumatic Caissons:

They are designed with a temporary roof near the bottom, and their bottom end can be used as a working chamber for the worker. The working chamber is filled with compressed air to prevent water from entering the chamber.

They can be made from steel or concrete, but the shaft is mostly made of steel because it is strong as well as easy to handle. Pneumatic caissons offer an opportunity to work in dry conditions underwater.

However, before descending, it should be made sure that the airlock is intact and the working chamber is safe to use. They have high construction costs, but they provide excellent working conditions underwater.

What are the Advantages and Disadvantages of Caissons?

Advantages of Caissons:

- Caissons are a very effective way to construct underwater foundations.

- They are affordable, and their construction cost is lower than other alternatives.

- They are relatively easy and clean to construct.

- They provide both horizontal and vertical load-bearing capacity.

- They can be constructed according to the site conditions or requirements.

- They are easy to handle and transport.

- With the construction of caissons, pile caps are no longer needed.

Disadvantages of Caissons:

- They require highly sensitive manufacturing processes.

- They are not a good choice for polluted places

- They need highly experienced labour to be constructed.

Process of Caisson Construction:

Prefabrication:

- Caissons are prefabricated close to the construction site, where they are easy to transport.

- After manufacturing, they are tested for water tightness.

- Any leakage is repaired immediately, if found.

Transportation:

- They are transported to the site after they pass the water tightness test.

- All the precautions must be taken when transporting caissons.

Installation:

- First, the caisson is properly positioned at the place using tug boats or anchors.

- When the caisson is placed properly, excavation can commence in the working chamber. Excavation can be done using both labours and other machines.

- The caisson will start to sink on its weight.

- When the caisson has reached the required depth, the working chamber is filled with concrete, and the caisson stops to sink further.

Ballasting:

- When fully sunk, they are ballasted properly.

- Ballasting will prevent any lateral movements of the caisson and help it to sustain maximum stability.

Drilled Pier Foundations (Caissons)

Drilled pier foundations are a type of deep foundation. They are constructed by drilling shafts into the ground and filling reinforced cement concrete into them.

The drilled shaft or borehole is penetrated to a stratum with the required bearing capacity. Then a steel casing is installed to prevent the hole from collapsing. After that, steel rebars are entered and the concrete is poured finally.

Drilled shafts can bear both horizontal and vertical loads. Their diameter can range from 45 cm to 365 cm. They have proved themselves to be cost-effective and strong.

Concrete Caissons:

A hole of 20 cm or 25 cm is drilled into the earth down to the bedrock. The steel rebars are inserted in the hole that runs through the full length of the caisson, which is followed by concrete.

A caisson is designed to stay on the stratum of sufficient bearing capacity when upper strata are not strong enough to sustain loads of the structure.

Straight Shaft Drilled Piers:

They are the most effective type of foundation when the subsoil is expansive. They are penetrated to a depth where moisture variation is minimum, so there is minimum damage from soil expansion.

The standard penetration depths for straight shaft drilled piers are a minimum of 2 metres and a maximum of 5 meters.